Inpico is mainly active in the food and beverage sector. The food sector can be divided into three domains: dairy, chocolate and additives. We carry out process, piping and construction work for each of these domains. We are also familiar with the strict hygienic standards that apply within this sector.

We have to take these strict EHEDG standards into account not only during design, but also during execution. Inpico's strength lies in linking the theoretical knowledge of the EHEDG standards with the practical implementation.

We have already helped several customers in the dairy industry. Not only pure piping projects, but also mixing installations for powdered liquids that are custom-built are part of our repertoire.

Business case: For one of our customers in the dairy industry, we installed a tipping installation for IBC containers. The tipping installation gives our customer the possibility to completely empty IBC containers. Valves were connected to the tipping installation in order to mix the product in doses.

Do you have a similar installation in mind? Would you like something else? Do you have any questions? Contact us and we will be happy to help.

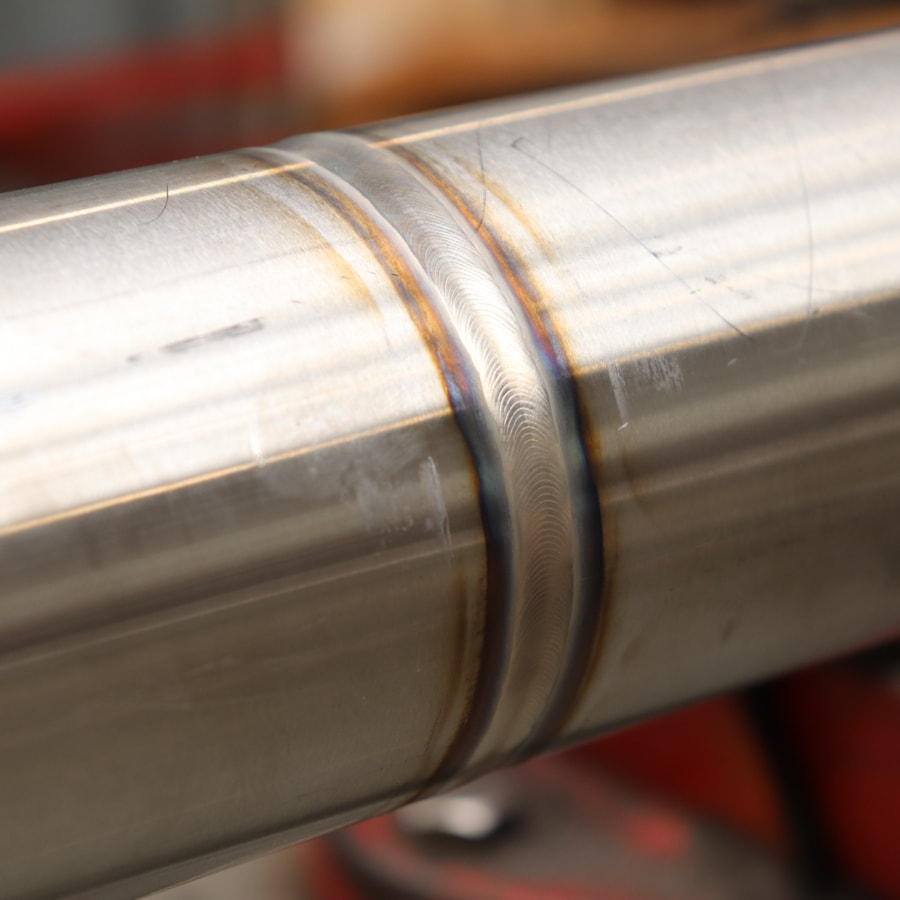

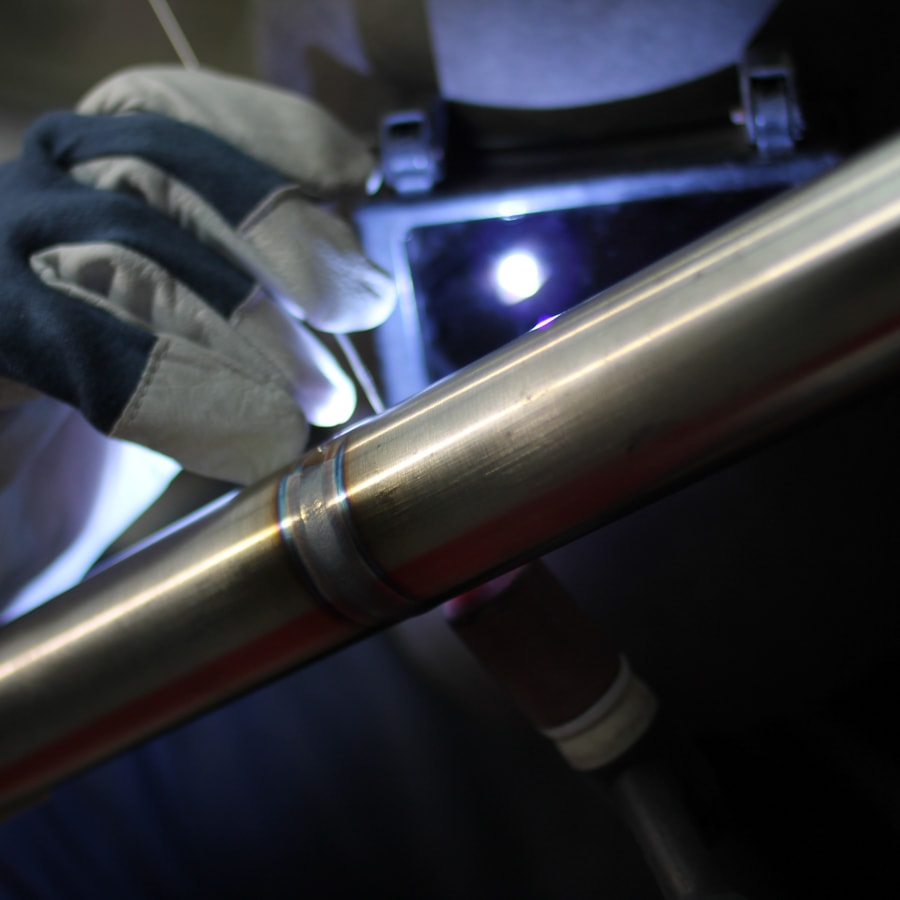

As a specialist in double-walled piping, Inpico has already realised a number of projects in the chocolate industry. With our self-designed system for double-walled piping, we have the possibility to realise the total integration of tanks and machines within the chocolate industry. Temperature control is particularly important when processing chocolate and let that be one of the applications of double-walled piping. The product in the inner tube, being melted chocolate, must be kept at a certain temperature, otherwise the chocolate will solidify. To keep the inner tube warm enough, hot water is passed through the outer tube. This keeps the chocolate liquid and allows it to be processed smoothly.

Are you interested in double walled piping? Any questions? Contact us and we will be happy to help!

The additives market within the food industry is a remarkably diverse one. Within this sector, we have experience with, for example, mixing installations for powdered liquids with various mixing principles: both mixing in a tank and mixing in a circulation loop have been covered within this sector.

Inpico often designs cleaning installations in connection with the production installation. The automation of the CIP (Cleaning in Place) varies according to the customer's requirements. A CIP installation is used for cleaning the product installation.

Questions? Interested? Contact us and we will be happy to see what we can do for you.